DYNICE® TOWING ROPES

The first DynIce Superwides were taken into use in 1993 as the first ones to replace steel wire on seismic vessels. Since then they have been preferred choice of the seismic companies.

The DynIce rope has less density than water and is therefore floating and the lightness makes handling easy.

DYNICE® TOWING ROPES

One of the main advantages is excellent abrasion resistance as the rope is constructed with double strands in 12 strand braid configuration. The double strand makes the surface more even than in a normal 12 strand rope where there are outer points which are prone to abrasion. The abrasion resistance is improved further with very durable coverbraid to protect the wide tow rope from abrasion and cutting.

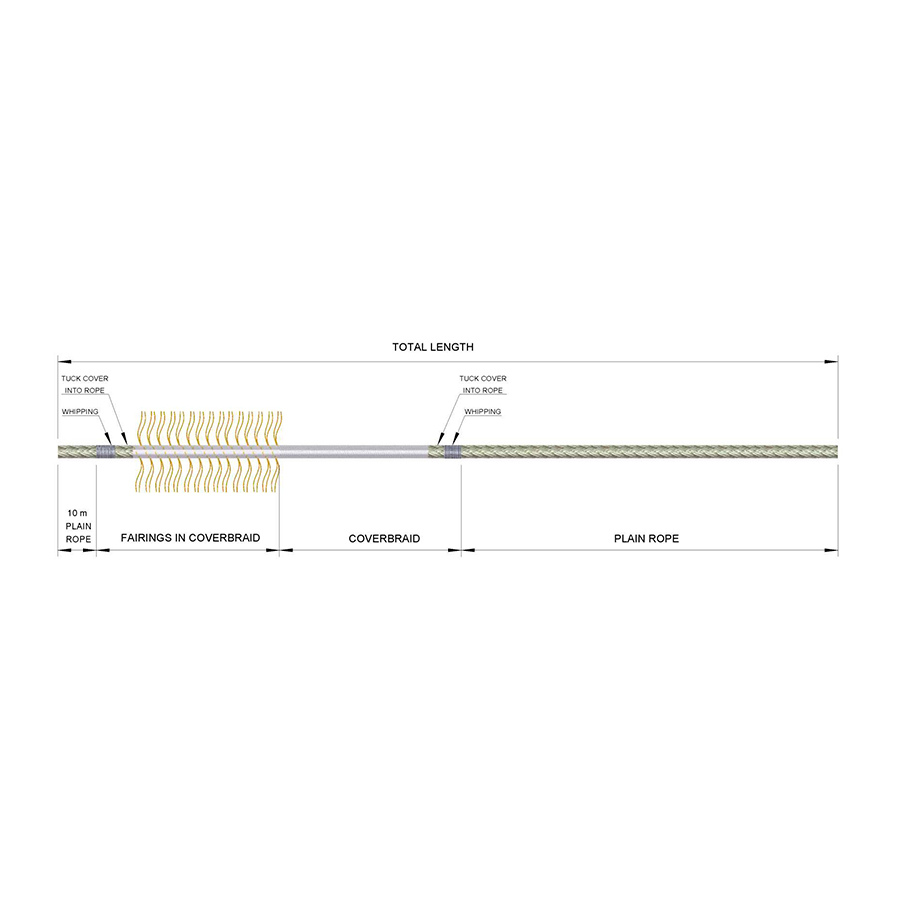

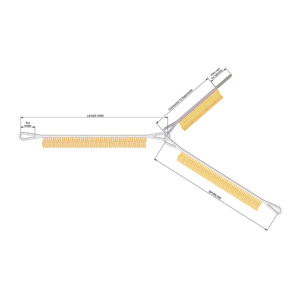

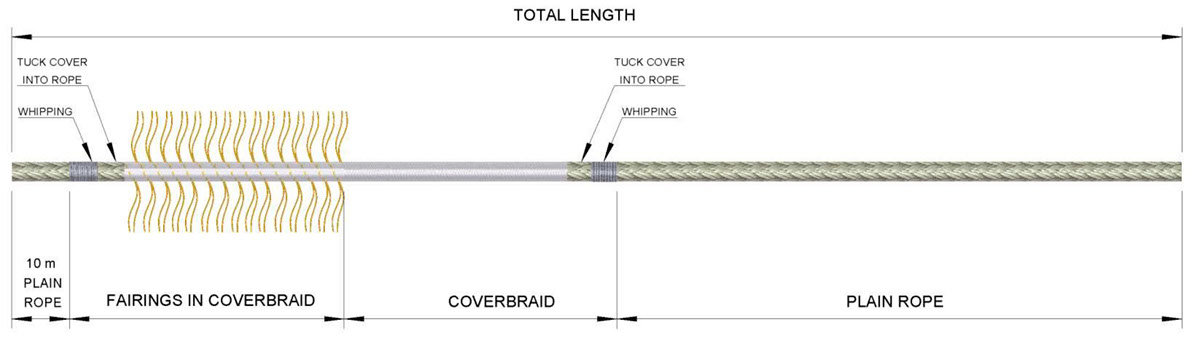

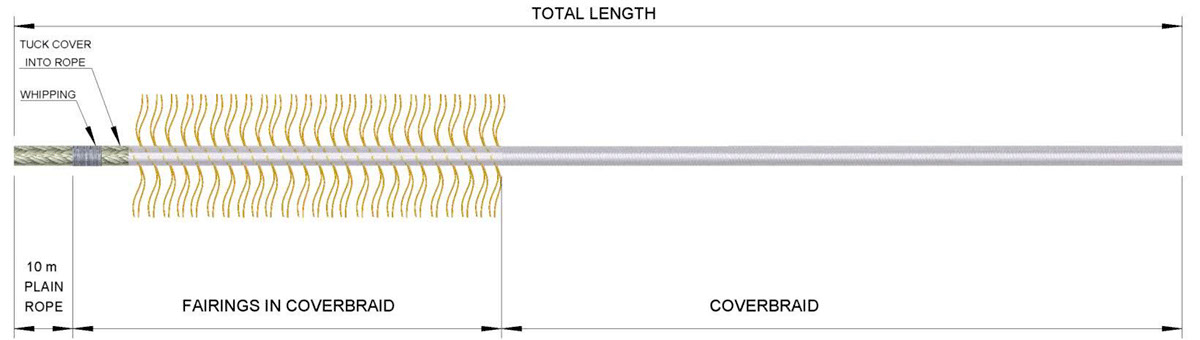

Each rope is made according to individual specifications but the main types are plain ropes for smaller seismic vessels and then partly or fully coverbraided ropes for the larger vessels.

PARTLY COVERBRAIDED

FULLY COVERBRAIDED

No downloads for this product.